- Home » News » Technology News

‘Breakthrough’ in calculations could double bearing lives

The Japanese bearings-maker NSK claims that it can revise the basic dynamic load rating of many of its rolling bearings to double their rolling contact fatigue life without any changes to their design or materials, following a “breakthrough” in the way bearing lives are calculated – the first significant change to these calculations in more than 60 years. The development will help end-users to improve productivity, cut the frequency with which they need to replace their bearings, and reduce waste.

The fundamental formulae used to calculate bearing lives have hardly changed from those defined in a report issued in 1962 by the International Federation of the National Standardizing Associations (ISA) – the forerunner of the current ISO (International Organization for Standardization). Now, more than six decades later, NSK says it has learned more about calculating and predicting bearing lives, making it time to reconsider how we evaluate this critical parameter.

The project started around 20 years ago, when NSK noticed a growing gap between bearing lives calculated using the ISO standard and actual bearing lives verified by endurance testing. It embarked on a more detailed study.

At the time, NSK found that the lives of its bearings were around 20 times longer than those expected under the ISO standards. Now, in 2024, the lives of its bearings can be more than 50 times longer. Longer bearing lives can improve production efficiency and protect the environment by reducing the frequency with which bearings are replaced, and the quantity of waste generated.

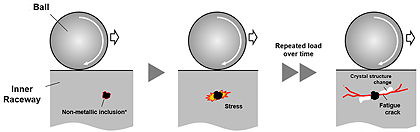

NSK’s research revealed that, under well-lubricated conditions, the composition and the quality of bearing steel is a more accurate indicator of how long a bearing will last. Its engineers realised that an evaluation method based on fracture mechanics might provide more meaningful insights into bearing lives.

The company embarked on joint project with Kyushu University to establish a method that could determine which factors influenced the process of crack propagation in the steel materials. By combining the new method with an ultrasonic inspection technique that scans non-metallic inclusions in large volumes of steel, NSK found it could predict bearing lives much more accurately.

Using this ultrasonic inspection method – called Micro-UT – it is possible to inspect more than 3,000 times the volume of steel compared with conventional microscope-based methods, in a fifth of the time.

NSK is now reviewing the basic dynamic load ratings of its rolling bearings to determine appropriate safety margins. It assures customers that the updating process will be based on a well-researched methodology supported by extensive empirical data. Any uprated values will remain well within the safe range.