- Home » News » Technology News

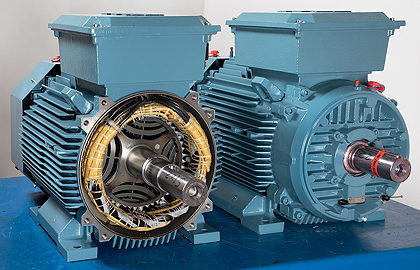

IE5 motors for hazardous areas are a ‘world first’

ABB has launched what it claims is the world’s first IE5-efficiency motor designed for use explosive environments. It says that the hazardous areas version of its IE5 SynRM (synchronous reluctance motor) will cut energy losses by up to 40% compared to the IE3 motors that are commonly used in hazardous area applications.

The IE5 SynRM Increased Safety motor is designed for a wide range of demanding variable-speed industrial applications. It offers accurate control and high efficiency across the whole speed range, even at partial loads. It can be used to upgrade standard induction motors for pump, fan and compressor applications in industries where explosive gases, vapours or dust might be present – such as oil and gas, chemicals, wood processing and flour milling.

The motors are available with output powers of 5.5–315kW, in IEC frame sizes 132-315.

In Zone 1 hazardous area applications, the cooler running design could allow increased safety motors to be used where a flameproof motor with a special enclosure would have been the traditional choice.

In Zone 2 applications, the improved “loadability” of synchronous reluctance motors allows more power to be delivered from the same size as an induction motor. This could enable smaller, and therefore lower-cost, motors to fulfil the same duty.

“We have achieved a significant world-first by bringing the benefits of IE5 ultra-premium efficiency to the hazardous area sector,” says Stefan Floeck, president of ABB’s IEC Low Voltage Motors division. “Adopting best-in-class technology has made our IE5 SynRM motors a game-changer for operators in a wide range of industries. They see the capability to improve energy-efficiency as key to achieving their net zero ambitions while optimizing their business costs.”

A key benefit of IE5 SynRM Increased Safety motors is that they run cooler than standard designs. Bearing temperatures are up to 15°C lower and winding temperatures up to 30°C lower. This increases reliability, prolongs the motor’s lifetime, and reduces the need for maintenance.

The synchronous reluctance technology combines the performance of permanent magnet motors, with the simplicity and service-friendliness of induction motors. The motors do not contain magnets or rare-earth metals.

The hazardous area IE5 motors were previewed at the SPS exhibition in Germany in November 2022.

ABB: Twitter LinkedIn Facebook