- Home » News » Technology News

UK-developed 28kg motor delivers 650kW and 398Nm

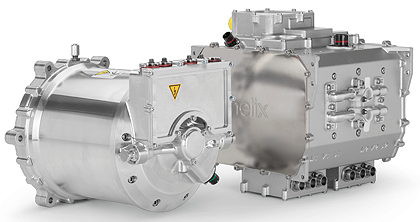

A British electric drive developer – Milton-Keynes-based Helix – has produced an electric motor that weighs only 28kg, yet is capable of delivering 650kW of continuous power and 398Nm of continuous torque. The 261mm-long and 206mm-diameter motor has a maximum speed of 25,000 rpm.

Helix developed the SPX177 motor for an unidentified hypercar manufacturer who wanted to power a vehicle with a single 650kW motor.

The motor weighs less than 1/7th as much as the latest, boosted internal combustion engines – such as those used in the McLaren Artura – producing an equivalent continuous power output.

Helix’s X-Division engineered the motor to minimise losses and heat generation, especially at high speed. They wound the motor to reduce losses through resistance, creating a low-inductance machine.

“It’s small and weighs just 41kg, including the 13kg inverter,” says Helix’s chief engineer, Derek Jordanou-Bailey. “It is a 2 x 3-phase motor, so its current is shared across two inverters – a necessary approach to meet the phase current demands at ‘normal’ DC voltages at this extremely high power level. Both the motor and inverter have extremely high power densities. Six high-voltage cables connect the inverter to the motor, while an LV connector carries the various control signals.

“The customer told us what peak power they wanted and demanded a very high steady-state output,” Jordanou-Bailey recalls. “Right now, it is tricky to deliver sufficient energy to maintain that level of output, but in time it is likely to be possible and the customer wanted to ensure their flagship model was ready for that.

“We needed an architecture that minimises losses and the heat generated, especially at high speed, and that meant quite a change in the way the motor was wound, since minimising resistance losses results in a very low-inductance machine,” he adds. “The switching in the inverter can generate lots of noise and harmonics and this is more challenging with a low-inductance motor. The software team did a great job developing a new way of controlling the phase currents.”

On a test stand, the motor has delivered a peak of more than 700kW. “It could potentially deliver more, we didn’t push it,” says Jordanou-Bailey. “We designed the motor and solved the control issues, while the onboard cooling was also very well thought out. We never considered ‘it’ll do,’ – we looked at everything and did the best job we could. And this is the result, a motor that cools remarkably well and delivers record-breaking steady-state power.”

He concedes that the vehicle’s battery will weigh much more than an internal combustion engine’s fuel store, but argues that the motor’s low mass allows flexibility in terms of where it is installed, helping to optimise the car’s architecture for a low centre of gravity and cleaner aerodynamics, for example.

There is a proposal to build a small initial batch of the motors. Helix is supporting the customer’s integration of the machine into its vehicle. “Then there’ll be liaison with their software team, but since the motor and inverter are already paired, we expect it to largely be plug-and-play,” Jordanou-Bailey concludes.

Helix: Twitter LinkedIn Facebook