- Home » News » Technology News

Plastic magnet rotors ‘could revolutionise’ high-speed motors

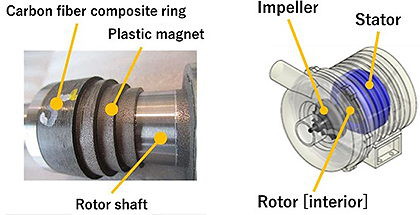

The Japanese manufacturer IHI has developed a “breakthrough” prototype high-flux plastic magnet rotor for use in ultra-high-speed motors, that would be would be efficient, lightweight and compact. IHI says these motors could revolutionise the production, performance and economy of electric aircraft and automotive propulsion systems.

The new rotors are produced by injection-moulding molten plastic and powder magnet composites, and casing them in a high-strength carbon-fibre-reinforced polymer ring, to create a structure that can withstand motor speeds of more than 100,000 rpm. The use of injection-moulding techniques reduces the need for machining, cutting manufacturing times and costs.

Tests by Japan’s Joint Research Centre for Electric Architecture (run by Akita University and Akita Prefectural University) have found that the performance of the prototype rotor matched or bettered that of sintered magnet rotors in which conventional magnets produce all of the magnetic force. The new rotors could halve the use of rare-earth materials by delivering the same output using magnets that are almost 50% plastic.

During the moulding process, a magnetic field is applied to align crystals in the plastic magnetic material. This strengthens magnetic forces in specific directions and orientates them to maximise the magnet utilisation efficiency.

The magnetic field is similar to what is known as a “Halbach array”. In a conventional magnet set-up, both sides of the magnet have similar magnetic field strengths. In a Halbach array, permanent magnets are arranged to augment the magnetic field on one side and reduce it almost to zero on the other side, thus maximising the magnet usage efficiency.

IHI is developing electric hybrid propulsion systems for aircraft with a view to practical deployment in the 2030s. It is also working on electrifying and optimising entire aircraft systems.