- Home » News » Technology News

Synthetic images ‘revolutionise’ vision system training

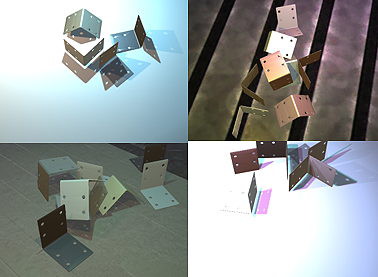

Siemens has launched a service that uses AI (artificial intelligence) to generate synthetic images of objects from CAD files. These images can then be used to simplify the training of machine vision systems to identify the objects.

Although the use of machine learning for vision-based automation is growing for applications such as robotic bin-picking, sorting, palletising and quality inspections, it can be difficult to implement because of the need to collect many images of the parts being handled and the challenges of annotating the items in those images accurately – especially before production starts.

To solve this challenge, synthetic data – computer-generated simulation – is being used increasingly to speed up data collection and training. However, using synthetic data for vision applications requires expertise in generating synthetic images and can be complex, time-consuming and costly. Siemens Digital Industries Software claims that its SynthAI service changes this.

Rather than waiting for pre-production parts to be ready or using complex processes to generate synthetic data, users provide 3D CAD data of their parts. The software then generates thousands of randomised, annotated synthetic images of the parts within minutes, without requiring any specialist knowledge.

The tool also trains a machine-learning model automatically to detect products in real-life situations. Once the training is done, the trained model can be downloaded, tested and deployed offline – using no more than a little Python coding. For users who prefer to train their own systems, complete sets of synthetic images are available.

“The market for AI for machine vision is expected to reach $25bn by 2023, but there are many challenges facing those looking to take advantage of its benefits,” points out Zvi Feuer, senior vice-president and general manager of digital manufacturing at Siemens Digital Industries Software. “SynthAI demonstrates how Siemens is taking its depth of knowledge in both product engineering systems, as well as production preparation and planning, and finding room for innovations that allow our customers to take advantage of tomorrow’s technology, today.”

An early adopter of the SynthAI technology has been the Israeli robotics developer, Polygon Technologies. “We were looking for a quick and easy solution that will enable us to detect wire terminals in a robotic electric cabinet assembly station,” recalls CEO, Omer Einav. “With SynthAI our control engineers were able to achieve great results within just a few hours. The tedious task of annotating a large set of training images to train the model was shortened significantly. The results show great promise for many additional use cases we plan to handle with SynthAI."

Siemens Digital Industries Software: Twitter LinkedIn Facebook