- Home » News » Technology News

Process recovers 98% of rare-earths from assembled motors

The car-maker Nissan has tied up with researchers at a Japanese university to develop a process for recovering rare-earth materials from electric motor magnets. They have started testing the process with the aim of making it a commercial reality by the mid-2020s.

Tests have shown that the process can recover 98% of a motor’s rare-earth elements (REEs). It also halves time taken to recover the materials compared to other methods, because there is no need to demagnetise the magnets, nor to remove and disassemble them from the motor.

The process is aimed, in particular, at motors used in in electric vehicles, most of which rely on powerful neodymium magnets containing scarce rare-earth metals such as neodymium and dysprosium. China dominates the supply of these materials and this has led to wide fluctuations in price and availability. The ability to recycle REEs would reduce dependence on China and on the environmentally damaging processes used to mine and refine the materials.

Nissan has been working on techniques for cutting the amount of REEs used in motor magnets since 2010. For example, the latest version of its Leaf EV uses magnets with 85% less heavy REEs than the 2010 model.

The company has also been recycling REEs by removing magnets from faulty motors and returning them to suppliers. But these processes involve multiple steps, including manual disassembly. Developing a simpler, more economical process is important if recycling is to increase.

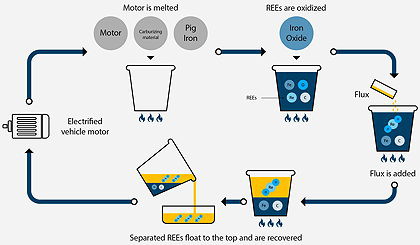

Nissan has been collaborating with researchers at Waseda University since 2017, and last year they announced a pyrometallurgy process that does not require motor disassembly. The five-step process includes:

• adding a carburising material and pig iron to the motor, which is then heated to at least 1,400°C and starts to melt;

• adding iron oxide to oxidise the REEs in the molten mixture;

• using a borate-based flux to dissolve the rare-earth oxides and recover the REEs;

• separating the molten mixture into two liquid layers, with a molten oxide layer (slag) containing the REEs floating to the top, and a higher density iron-carbon alloy layer sinking to the bottom; and finally

• recovering the REEs from the slag.

Waseda and Nissan are continuing large-scale testing of the process with the aim of developing a commercial version. Nissan will collect motors from EVs that are being recycled and will continue to develop its own recycling system.

Nissan: Twitter LinkedIn Facebook