- Home » News » Technology News

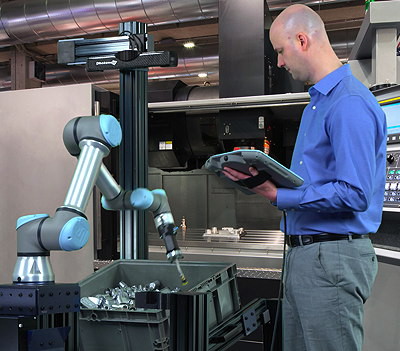

Autonomous bin-picking cobot puts parts into machines

The Danish collaborative robot (cobot) specialist Universal Robots (UR) has announced a kit that, it says, will simplify the integration of autonomous bin-picking of parts and accurate placement in machines using its cobots. The ActiNav autonomous bin-picking kit synchronises vision processing, collision-free motion planning, and autonomous real-time robot control, eliminating the complexity and risk usually associated with bin-picking applications.

These applications usually require substantial efforts in terms of both integration and programming. Most existing bin-picking products concentrate on the vision aspect of the picking operation and often need hundreds of lines of additional programming to bridge the gap from “picking” to “placing” – especially if the “placing” is not simply dropping items into a box or tote, but inserting them accurately into fixtures for further processing. UR says that the new kit will allow manufacturers with limited or no bin-picking expertise to achieve high machine uptime and accurate parts placements with few operator interventions.

The ActiNav kit combines autonomous real-time motion control, collaborative robotics, vision and sensor systems in an easy-to-use, fast-to-deploy and cost-effective way. It needs no vision or robot programming expertise, but is based on a “teach-by-demonstration” principle, using a six-step, wizard-guided set-up process integrated into a cobot teaching pendant. According to UR, it can be deployed easily and quickly by manufacturers’ in-house automation teams – or with help from a distributor or integrator – to boost productivity, quality and efficiency.

“Machine tending has always been one of the mainstay applications for our collaborative robot arms,” says Jim Lawton, UR’s vice-president of product and applications management. “We discovered a significant market need for a simple solution that enables UR cobots to autonomously locate and pick parts out of deep bins and place them precisely into a machine. This is not pick-and-drop; it is accurate pick and part-oriented placement.”

There are various approaches to automating machine-tending stations, many of which use trays, bowl feeders or conveyors to get the parts to the machine. ActiNav bypasses this step. “Parts are often already in bins, so the most flexible and scalable option is to deliver that bin of parts to the machine and then pick them directly from the bin and place them into the machine,” explains Lawton. “This minimises floor space and reduces the need for part-specific tooling.”

The system can insert parts autonomously into CNC or processing equipment, such as drilling, deburring, welding, trimming or tapping machines. A high-resolution 3D sensor and CAD matching allow accurate picks using an “autonomous motion module” that decides how to pick the part, then controls the robot to pick the part and place it into a fixture. The module allows the cobot arm to operate inside deep bins that hold more parts – something that standalone bin-picking vision systems struggle to do, according to UR.

The bin-picking kit is available from UR’s distributors and via the new UR+ application kits platform – an expansion of the UR+ ecosystem of components certified to work with UR cobots. Like other UR+ kits, ActiNav eliminates duplicated engineering efforts when deploying common applications. It works with the UR5e and UR10e e-Series cobots, a UR+ component or user-defined end-effector, and application-specific frames or fixtures. The kit includes the autonomous motion module, interface software, and a choice of 3D sensors.

Remy Glaisner, robotics research director at the analyst IDC, predicts that the bin-picking kit “will set a new level of operational expectations regarding the future of intelligent systems”.