UK's £9m 5G manufacturing project is the largest

The UK government has announced its biggest investment in using 5G for manufacturing to date – a £9m ($11.7m) project that will install a private 5G network at the National Composites Centre (NCC) in Bristol. The multi-partner project, called 5G-Encode, will explore new business models for private 5G networks in industrial settings and test new 5G technologies, such as network splicing and slicing, in a real working environments. It will also examine the practical application of 5G wireless technologies to improve composite design and production processes.

The 11-member consortium is being led by the Bristol-based networking specialist, Zeetta Networks. Other participants include the NCC, Siemens, Toshiba, Telefonica, Solvay, Baker Hughes, Plataine, Mativision, the University of Bristol and the West of England Combined Authority (WECA).

The project will investigate three industrial 5G use cases aimed at improving productivity and effectiveness in composite design and manufacturing. Each has the potential to save UK manufacturers hundreds of millions of pounds. They are:

• using interactive augmented reality (AR) and virtual reality (VR) to improve design, training and maintenance in composite manufacturing;

• using network splicing to track time-critical assets across multiple sites, indoors and outdoors, and potentially across national borders; and

• using 5G’s reliable low-latency communications to monitor and manage industrial systems that will be more responsive than current networking technologies allow, thus preventing wastage.

The project will look at the most cost-effective methods of delivering 5G in industrial settings. It will also examine new business models for private mobile networks in the manufacturing sector. Examples include neutral hosting, the sharing of in-building infrastructure by mobile operators to provide full coverage inside buildings, and spectrum pooling and sharing where licensed and unlicensed spectra could be shared between private and public network operators.

The project started last month and is aiming to deliver “real-life impact” by September of this year. It will run until March 2022, by which time commercial 5G deployments are expected across a variety of manufacturing sites in the UK. The project is part of the Industrial 5G Testbeds and Trials programme being run by the Department of Culture, Media and Sport (DCMS).

“5G is about more than consumers getting faster and more reliable speeds,” says DCMS secretary of state, Oliver Dowden. “We’re determined to harness this revolutionary technology to boost the productivity and growth of UK industries. We want Britain to be a world leader in 5G and since 2017 the government has invested millions in ground-breaking testbeds and trials across the country to achieve this.”

The NCC’s chief technology officer, Dr Enrique Garcia, adds that the 5G testbed “will showcase a step change in security, reliability and connectivity, providing companies of all sizes a risk-free environment to evaluate and capitalise on the capabilities offered by 5G”.

Among other things, the project will test techniques developed by Zeetta for 5G network splicing and slicing. Network slicing is the ability to define and provide prioritised, partitioned and protected sub-networks, allowing business and time-critical systems to run on shared infrastructures without interfering with each other. Network splicing allows slices to be joined in sequence to extend reach to provide a continuous service.

These technologies are expected to play an important role in manufacturing applications, particularly where assets must be tracked across multiple sites, geographic locations, and indoor and outdoor environments. The project will examine these capabilities as enablers for the wider adoption of 5G in the industrial sector.

“The ability to dynamically slice the resources of the network according to the demands of users and applications is a fundamental difference between 5G and previous mobile technologies and it is expected to play a transformational role in improving industrial productivity,” explains Zeetta’s CEO, Vassilis Seferidis.

Zeetta has an expertise in software-defined networking (SDN), which it will use with its NetOS Rapide private network and Multi-Domain Orchestrator (MDO), to manage the 5G network dynamically and allow various industrial applications and services to be delivered over the same network.

The 5G-Encode project will also test an AI (Artificial Intelligence) based industrial IoT technology that supports material and asset tracking, predictive alerts and optimised recommendations. This technology, developed by an Israeli company called Plataine – a member of the consortium – will use AI-based digital assistants, integrated with a network of sensors, to deliver material shelf-life tracking, management and optimisation capabilities. It will track time-sensitive raw materials automatically, predict remaining exposure times, and select the most appropriate material for each job, minimising waste and ensuring production deadlines are met, while maintaining full traceability of the products’ digital thread.

In addition, automated real-time tool-tracking will ensure that production schedules are not disrupted by lost tools. The AI-based digital assistants will provide predictive quality alerts, actionable insights, and real-time maintenance recommendations to staff.

“Automating and optimising manufacturing is absolutely at the core of Plataine’s offering, and we are very excited to be working on this ground-breaking project,” says the company’s president and CEO, Avner Ben-Bassat.

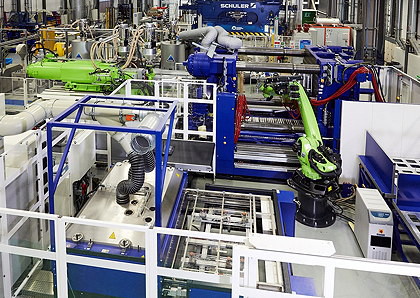

The National Composites Centre is one of seven centres that form the UK’s High Value Manufacturing Catapult. There are more than 350 composite specialists based at its Bristol facility, focusing on accelerating the adoption of high-value, sustainable composite technologies to stimulate growth and enhance the capabilities of this sector in the UK. It offers access to digital manufacturing technologies for the design and development of new composite products, from the lab to large-scale production.