- Home » News » World News

Global robot sales soar by 29% to hit a new record

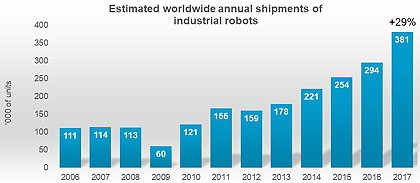

Global sales of industrial robots soared by 29% last year to hit a new record of 380,550, according to preliminary statistics released by the International Federation of Robotics (IFR) at the Automatica show in Germany. The 2017 sales were worth around $50bn.

The biggest driver of this increased demand has been China, where sales were 58% higher than in 2016, and 138,000 new industrial robots were installed during 2017. By comparison, sales in Germany were up 8% on 2016, with around 22,000 robots being sold. In the US, sales rose by 6% and 33,000 new robots were installed. During 2017, South Korea installed around 40,000 new industrial robots, while Japan added around 38,000.

Together, the five biggest markets – China, Korea, Japan, the US and Germany – accounted for 71% of all sales of industrial robots last year. The next five markets in order of size were Taiwan, Vietnam, Italy, Mexico and France.

In terms of applications, the automotive industry continues to be the world’s biggest user of industrial robots, with around 125,200 robots being sold to this sector during 2017 – a 21% increase on 2016. The fastest-growing sector during 2017 was the metals industry, which bought 54% more robots than in 2016, followed by the electrical/electronics sector with a 27% increase, and the food industry, where sales rose by 19%.

“The growth of industrial robots continues at an impressive pace worldwide,” comments IFR president, Junji Tsuda. “Key trends such as digitalisation, simplification and human-robot collaboration will certainly shape the future and drive forward rapid development.”

Trends that the IFR identifies in the industrial robots market include:

• increasing connections between real production and the virtual data world, opening up new possibilities for analysis and machine learning, with robots acquiring new skills through learning processes;

• simplified handling, with future industrial robots likely to be easier and faster to program using intuitive procedures, making them more attractive to small and medium-sized companies, who will be able to adopt robots without needing to use experts; and

• increased collaboration between humans and robots without protective barriers, leading to new forms of flexible production.

“In the future,” says the IFR, “human-robot collaboration will support the flexible production of small quantities with high complexity”.