- Home » News » Technology News

Groups of PLCs swap process and safety data in real time

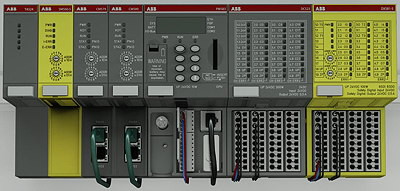

ABB has launched a series of safety CPU modules that can function both as safety controllers and safety devices, allowing users to move from a single central PLC to multiple PLCs, each capable of communicating with many machines. Each machine controller can exchange large volumes of process and safety data simultaneously in real-time with more than one central controller.

When used with ABB’s AC500/AC500-S PLCs, the new modules can exchange process and safety data, not only from one controller to multiple devices, but also from one device to multiple controllers, using Profinet/ProfiSafe shared device functions.

The hybrid interconnected PLCs can be used to extend traditional centralised or distributed control systems. Each controlled machine can deliver high volumes of process and safety data simultaneously in real-time to several central control systems.

This approach avoids the need for gateways which are expensive, occupy valuable control cabinet space and, because they are limited to only 12 bytes of safety data per gateway, cannot communicate large volumes of safety data in in real time. With the new system, up to 1,440 bytes of process data – including up to 384 bytes of functional safety data – can be allocated to up to four PLCs, thus speeding up reaction times to optimise production and to improve predictive maintenance, in turn reducing downtime.

The flexible, modular approach allows complex systems to be split into different tasks – such as central controls for production and storage handling, or automated controls and manual operator control stations. The data can be shared in real time with various central PLCs.

Furthermore, existing systems can be modified flexibly using add-on communication modules to exchange process and safety data. With distributed controls, where data flows from one system to another, the control logic is spread across the facility, enhancing system performance. The new control approach can be used to optimise such systems, with all of the control and safety data being available at a given time.

The new PLC modules are aimed at systems integrators who are building complex installations, yet require flexible controls. Typical applications include remote control of machines and equipment in production plants, distribution centres, airports and harbours. Often in such applications, the control system needs to be altered or updated when production is changed or extensions are made. During such upgrades or maintenance, the central control systems have to remain available. These could be manual locations with remote control access for unexpected occurrences.

Now, each machine can deliver the process and safety data simultaneously in real time, not only to several central control stations, but also to special control systems. For example, the status of the brakes on AGVs (automatic guided vehicles) can be monitored and analysed using on-board condition-monitoring and safety functions.

The modular architecture allows communication controller and device functions to extend existing control systems. Furthermore, a safety controller can re-use communication interfaces for standard controls, simplifying designs by separating the safety and standard control logic processing. With this approach, users can extend and modify existing controller/device topologies, using communication modules to perform safety and/or process data exchange between different control systems.

“Safe remote control of machines is becoming common,” says Yauheni Veryha, product manager for ABB’s AC500-S safety PLCs. “Today, typical real-time machine control is done by communicating only to one or two controllers. In the future, the communication to at least four control systems will be required. and later to eight or even more.

“With an increasing focus on collaboration, the next generation of automated industrial environments needs to be efficient, productive, scalable and safe,” he adds. “This solution goes a long way to increasing collaboration between machines, robots and people using flexible, safe and reliable communication.”