- Home » News » Technology News

Free app could save manufacturers more than $1m a year

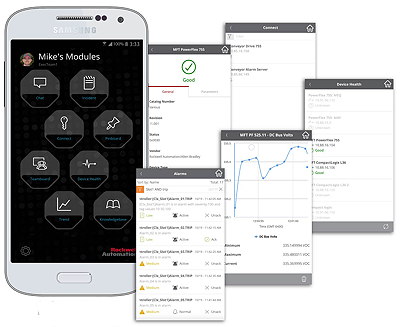

Rockwell Automation has released a free app for mobile devices such as smartphones that will allow engineering teams to collaborate and share knowledge, view live production statistics, interact with machine alarms and troubleshoot machines. Rockwell estimates that each team member using the FactoryTalk TeamOne app could save 1% of their workday, or 33 seconds per shift – equivalent to an annual saving of more than $1.4m for a manufacturer with about 2,000 production staff.

Rockwell has been developing the iOS or Android app – previously known as Project Stanton – for more than a year, in collaboration with Microsoft. More than 500 Rockwell customers have been using the app in a pilot phase since September 2016.

By offering near-instantaneous incident and device data, the app allows plant floor, engineering and IT workers to work together as a team to solve problems quickly. From their smartphones, they can view data from devices such as VSDs, or check the health of EtherNet/IP devices. They can then share this information with other team members. Once issues have been resolved, the results can be saved and searched for the next time a similar incident occurs.

“Industrial companies usually spend years and make significant capital investments in new technology to view data from machines before they even begin to see it pay off through productivity gains,” explains Kyle Reissner, mobility platform leader for Integrated Architecture at Rockwell. The app allows users to form a team and use their knowledge, along with device data, to improve productivity.

“The app doesn’t need teams to install servers, have pre-existing infrastructure like OPC servers, or connect automation assets and devices to the cloud in order to use the modules,” he adds.

Rockwell argues that, at present, when production lines experience a glitch, there is often not enough time for shopfloor workers to identify and find suitable colleagues. They have to deal with downtime events by connecting to servers, jumping between devices and data sources, running back and forth between information portals, and hunting down colleagues who may have expertise in the issue. The problems are made worse if workers do not have suitable visualisation functions, collaboration tools or information systems on their preferred devices.

The new app acts as a smart node, rather than as a client that connects to a server. Device modules within the app communicate directly with devices on a network, allowing data to be viewed live. When secure cloud access is available, the modules sync with other trusted team members.

The initial release, known as the FactoryTalk TeamOne Free Edition, includes eight modules known as: Incident; Device Health; Teamboard; Knowledgebase; Connect; Pinboard and Chat; Connect and Trend.

In 2017, Rockwell plans to offer a more powerful version, called FactoryTalk TeamOne Standard Edition, on an annual subscription basis. This version will include an extra alarm module, multiple team logins, and other functions based on user feedback.

“We view FactoryTalk TeamOne as the first app focused solely on increasing industrial worker productivity by converging team collaboration and automation-centric data,” says Reissner. “It’s a really exciting, innovative space where we’re planning to update often. In fact, we’re already planning for future modules, integration with FactoryTalk Analytics applications, and even contributed content.”

The app can be downloaded from Google Play or the Apple app store.