- Home » News » World News

Growing use of wireless poses risks to manufacturers

The growing use of wireless connections in factories is exposing production sites to security breaches and cyber-attacks, forcing companies to seek ways to protect their networks, according to a new white paper from IHS Technology.

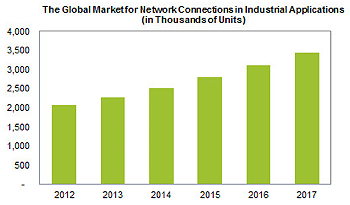

IHS predicts that the number of wireless network connections in factories will grow from 2.1 million in 2012 to 3.4 million by 2017, increasing the risk factors to manufacturing environments.

“The rising use of wireless networks and industrial Ethernet is leading to a growing trend in the so-called bring-your-own-device (BYOD) movement in the manufacturing business, with workers utilising their own smartphones and tablets to monitor and control industrial equipment,” says Mark Watson, associate director of IHS’s industrial automation group. “However, such devices may lack adequate security, offering hackers easy access to confidential data – or allowing them to spread malware through factory automation systems.”

To counter this threat, manufacturing operations are taking cyber-security measures. Among these is the “honeypot” - a site that masquerades as a manufacturing network but is actually an isolated system designed to divert and gather information about hackers.

Various wireless networking technologies are now being used in manufacturing, including.

• Wireless local area networks (WLANs) The most widely adopted protocol in industry is suitable for many applications. Advances in the enterprise and consumer sectors are allowing knowledge and technology to filter through to industrial applications.

• Bluetooth Another protocol used extensively in consumer applications that is also proving popular for industrial automation networking. It can pair devices, providing greater security and reducing the potential for opportunistic hacking attacks.

• WirelessHart and ISA 100.11a These are the two major “true” industrial wireless technologies. They compete directly and are more common in process industries than WLAN and Bluetooth, which are more commonly found in discrete industries.

IHS says that the current level of adoption of wireless in factory and process environments is low, but the technology’s presence is expanding, bringing both benefits – as well as increased risks from hackers – to the manufacturing market.

The issue of security in manufacturing networks became front-page news in 2010, when the Stuxnet computer worm hit industrial control systems in Iran. Stuxnet was designed both to subvert and to engage in the surveillance of supervisory control and data acquisition systems made by Siemens.

While Stuxnet is thought be an intelligence tool, other types of malware are designed to infect and cause damage to manufacturing systems. In some cases, hackers have blackmailed the manufacturing operations of companies, demanding ransoms to remove the malware from their systems.