- Home » News » Technology News

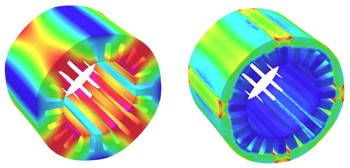

Vibration analyser speeds up machine designs

Cobham Technical Services has extended the capabilities of its Opera-3D finite element software for electromagnetic design, by adding a new solver that can analyse natural vibration modes. The tool is expected to be particularly useful for developers of electrical machines, who can use it to investigate and minimise forces that might cause oscillations close to a machine’s natural frequencies. They can thus avoid excessive vibrations or collisions between rotating and stationary parts.

By combining this analysis of vibrations with electromagnetic modelling – and thermal performance, if required – the 3D software suite can simplify and accelerate projects. It reduces the need to create physical prototypes to explore the behaviour of proposed designs. Accurate simulation allows real-world prototyping to be cut to a few iterations, taking months out of design cycles – along with the associated costs.

“Finite element simulation is the most practical tool for exploring design concepts and validating device performance,” says Jeremy Howard-Knight from Cobham. “Adoption from the outset of the design process can stimulate innovation and lead to designs which are right first time. With engineering skills at a premium, design automation using computer modelling is an extremely effective investment that companies can make to ensure successful products and a continuing flow of design ideas.”