Pump-maker’s synchronous reluctance motors meet IE4

A German pump manufacturer has started producing a range of super-premium efficiency IE4 motors that do not contain any magnetic materials, such as rare earths. As well as using the SuPremE motors to drive its own pumping equipment, KSB Aktiengesellschaft plans to sell them to other users.

The synchronous reluctance motors are said to dissipate at least 15% less power than IE3 motors and can already meet the proposed IE4 efficiency level. In contrast to asynchronous motors, the synchronous reluctance machines have a good efficiency even when they are run at part loads. This is often the case in day-to-day operations, where many motors in speed-controlled applications run mainly at a reduced speeds.

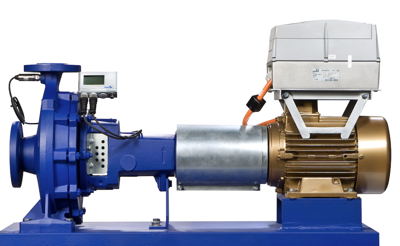

The new motors (shown above integrated in a pumping system) have four-pole rotors consisting of a laminated core without a cage. The laminations are shaped to guide the lines of flux. The motors do not need failure-prone rotor position sensors, making them as robust and reliable as speed-controlled asynchronous motors, according to KSB. Also, because of the low rotor operating temperatures, the motors are expected to have long bearing lives.

Combined with KSB’s PumpDrive variable speed system, the motors can operate at speeds from 0–4,200 rpm.