Compact gear-motor will have a 38mm hollow shaft

A novel hollow-shaft geared motor will be a highlight of Stöber’s stand at next month’s Hannover Fair in Germany. The company first previewed its PipeDrive at the SPS/IPC/Drives show in Nuremberg at the end of 2009, but the innovative design – with novel motor windings and a new gear design – has taken longer than expected to put into production. It is now due to start shipping at the end of May.

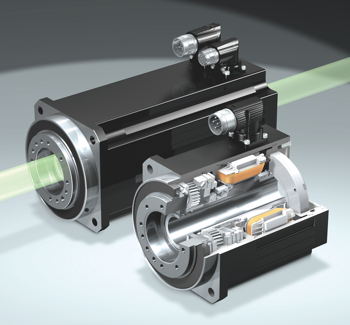

One of the PipeDrive’s most noticeable characteristics is its unusually large hollow shaft, with an internal diameter of 28 or 38mm. This makes it large enough to accommodate supply lines including not only power cables, hydraulic pipes and pneumatic hoses, but also shafts and laser beams.

To achieve these dimensions, Stöber had to develop an extremely short, hollow-shaft planetary gear. To protect the media that will be fed through the flange hollow-shaft, it is clad with one continuous pipe.

The servomotor’s short length has been achieved using a novel winding technology (known as orthocyclic linear winding) that generates the highest possible copper fill factor. The coils are not laid directly on top of each other, but are offset slightly. This is said to increase the power density by about 80% compared to previous winding technologies, allowing the motor to be shorter.

Stöber is one of the first motor manufacturers to use this winding technique, which was developed by a Swiss company. The winding is done using an automated process, resulting in more accurate windings than previous manual techniques.

The gear’s output drive bearing provides a high level of tilting stiffness, allowing for a high, yet reliable, tilting moment.

Because external fans cannot be used with hollow-shaft drives, liquid cooling is available as an option, boosting the nominal torque by about 30%. The process cools the gears as well as the motor and produces waste heat that can be recovered via heat exchangers.

Stöber says that the PipeDrive offers a balance between high torque, high dynamic performance and precise constant speed. Its dynamic behaviour can be modified.

The planetary gears will be available in one to three stages with ratios from 3 to 27. Acceleration torque will cover the range 30–500Nm, and the hollow-shaft motors will be available in four lengths with 25mm increments.