Novel rack-and-pinion design leads to smaller gear sizes

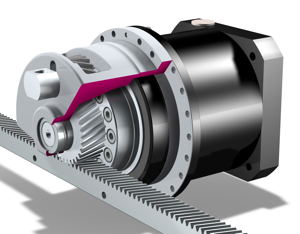

The German geared drives manufacturer Stober has joined forces with the rack specialist Atlanta to develop a compact, efficient rack-and-pinion drive system with a built-in output bearing housing – a stiff supporting assembly for the pinion which relieves the load on the flange-mounted planetary gear bearings.

The reduced tilting moment of this construction makes it possible to design the drive based on the torque that is actually needed, as well as the feed force. This will often mean that smaller gears can be used than in the past.

Because of the comparatively small pinions, a higher output speed is needed to obtain the required feed rate. This means that the gear ratio is lower and, in many cases, a single-stage planetary gear system can be used instead of a two-stage.

According to Stober, this gives the HighForce ZTRS-PH(A) rack-and-pinion drive (shown above) an extremely high power density and could encourage machine-builders to redesign their machines.

Previously, rack-and-pinion drives have usually been developed from a planetary gear with a gearwheel fitted to the output shaft, and a matching gear rack. But the overhung load on the gear from this arrangement can be so high that it determines the dimensioning and, typically, only 40–60% of the gear’s torque is used.

Because the pinions in the new design do not have to be flange-mounted directly onto the gear flange shaft`s bolt circle, linear stiffness is also improved. The new mounting system makes it possible to use rack pinions with few pinion teeth, increasing linear stiffness by up to 100%. Linear backlash has also been reduced by 40%, and the pinion concentricity adjusted to ≤0.01mm.