Oil-free compressor is `biggest revolution for 50 years`

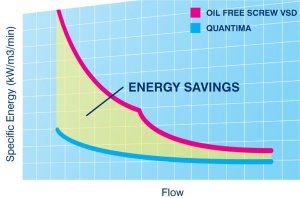

Following five years of development, the UK compressor manufacturer CompAir has unveiled an oil-free compressor with just one moving part, which it describes as "the biggest revolution in compressed air technology for 50 years". The company says that the low-maintenance, low-noise Quantima compressor uses up to 25% less energy than conventional compressors, and is half their weight and size.

The heart of the compressor (above) is a rotor (shown below) that floats on active electromagnetic bearings and can reach speeds of up to 60,000 rpm. The rotor is spun by a direct-drive, inverter-controlled asynchronous induction motor that varies its speed to match the compressor air flow to plant demand. The patented high-speed motor avoids the need for gearboxes and lubrication. Off-load power consumption is just 2.5% of full-load power – the lowest of any compressor, according to CompAir.

Unlike conventional compressors, which typically have seven gears, the new design has none. It needs just four bearings, whereas conventional compressors can have up to 19, and it uses just two seals in contrast to the 17 found in standard designs. The compressor is available in four power ratings from 150-300kW, weighing 2.4-2.6 tonnes.

Noise levels are claimed to be much lower than usual – 69 dB(A) compared to 74dB(A) for a typical conventional system – allowing the compressor to be sited near where the air is being used, and allowing people to work nearby without needing ear protection.

"It is very rare that you can develop a product that will fundamentally change the way an industry thinks," says CompAir’s chief executive, Nick Sanders. "With Quantima, this is what we have achieved."

Energy typically accounts for more than 80% of a compressor’s total cost of ownership over its lifetime. CompAir estimates that if the new compressor uses 20% less energy than a conventional screw design, it will save €480,000 over a typical ten-year operating cycle (based on a 300kW machine operating for 8,000 hours a year on electricity costing €0.10/kWh). CompAir reckons that the potential reductions in CO2 emissions for one compressor are equivalent to taking 75 cars off the road.

Further savings are possible using optional energy recovery kits that can recycle up to 75% of waste heat from the compression process for other uses, such as heating water.

CompAir asserts that the new design will also help to cut the maintenance and repair costs that typically account for about 8% of a compressor’s lifecycle costs. The absence of contacting parts (and thus friction) in the compressor assembly, coupled with the reduction in component numbers, will boost reliability, the company suggests.

This will be backed up by a built-in predictive maintenance system which will keep an eye on the system continuously. Key parameters will be monitored remotely from a service centre that can dispatch engineers to replace any problem components before failures occur.

Unlike conventional maintenance programmes which require compressors to be taken out of service at fixed intervals, CompAir says that the remote monitoring facility will allow it to change parts only when needed, thus avoiding unnecessary shutdowns. It is backing the compressors with a ten-year warranty.

"In launching Quantima, we have opened the door to the fast-growing oil-free market and placed ourselves in the driving seat of this strategically important sector," says CompAir CEO, Nick Sanders. "Having brought this technological revolution to the global marketplace, we are now leading the industry and are determined to stay one step ahead."