New magnetic material `will halve the cost of building motors`

Researchers in Sweden have found a new way of making magnetic components that, they claim, will halve the costs of producing electric motors, as well as almost doubling their outputs. The development is the result of 15 years of collaboration between researchers from the fields of electrical power systems and industrial production in Lund University’s Faculty of Engineering.

Traditionally, the magnetic materials used in motors are formed from bundles of thin laminated sheets with coils wound around them. But this approach requires many small parts and takes a long time to manufacture.

"Electric motors have largely been made in the same way since the 1850s," says Mats Alküla, professor of electrical power systems in the university’s faculty of engineering. "Only in the past 10-15 years, have alternative production methods been studied."

Working with his colleagues Tord Cedell and Mats Andersson, Alküla has found that an alloy of iron powder and plastic can work well in motor applications, and deliver high energy efficiencies.

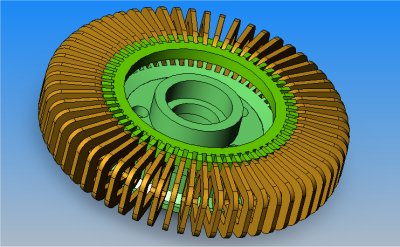

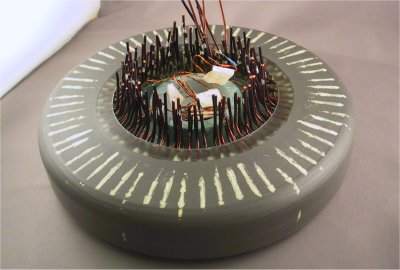

By moulding melted plastic and iron particles – which make the part weakly magnetic – parts can be formed into any shape. The technique also cuts the number of production steps from about 60 to a handful. A computer-generated model of one design is shown above, and a prototype version of the motor below.

"The technique is not suitable for high-performance motors, such as servo motors," Alküla explains, "but for fans, pumps, household appliances, and cars it’s a perfect fit." He predicts that it could "pave the way for new possibilities, such as facilitating the conversion of cars to electric hybrid power".

Development work on the new material started in the late 1980s in Lund university’s industrial production department as part of a materials technology consortium, funded partly by a Swedish government programme, now called Research and Innovation for Sustainable Growth. Over a five-year period, the total funding has amounted to around SEK12m (Ł920,000).

A technology is protected by a patent. The University’s Centre for Electromagnetic Energy Conversion (Cemec) has yet to decide whether to form a new company to commercialise the technology, or to licence it to potential users.