- Home » News » Technology News

Project aims to offer a second life to motor components

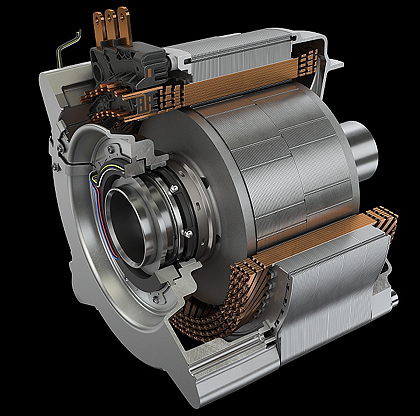

A consortium of German organisations, led by Schaeffler, is developing techniques that will allow electric motor components to be re-used at the end of the motor’s life, rather than being shredded and recycled, as happens at present.

Members of the Reassert project – which is being funded by the EU and the German government – are pursuing various concepts for repairing, remanufacturing and re-using electric motors. The project also aims to develop a prototype electric motor suitable for the circular economy.

Electric motors contain valuable raw materials including copper and electrical steel, as well as rare-earths such as neodymium, which cannot be recovered using current recycling methods. Hence, extending the use of the motors is becoming increasingly important. Another factor that applies in particular to electric vehicle motors is that their raw materials have larger carbon footprints than those used in combustion engines.

At present, materials such as copper and aluminium can be recovered from old motors using manual or automated recycling methods. Electric traction motors, in particular, can be disassembled, shredded, sorted into individual materials which are then melted down for recycling. However, the recycled materials, which are often contaminated, cannot usually be used in new motors, and the individual components and assemblies are destroyed in the recycling process.

According to circular economy principles, raw material recycling should only be chosen as a last resort and replaced instead by strategies that preserve value, such as re-use, repair and remanufacturing.

“We want to establish a closed-loop system in which valuable resources are re-used to eliminate dependency on raw material imports and to minimise raw material extraction,” explains Julian Große Erdmann, a scientist at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, which is a member of the Reassert consortium.

“With these strategies, fewer raw materials like rare-earths, copper and others are needed, perhaps only for spare parts,” he adds. For raw material recycling, the project partners want to be able to disassemble motors and sort the materials before shredding. They are using EV motors to analyse and select which strategies to use.

The partners define re-use as re-using the entire motor for a secondary role, and repair as replacing defective parts and assemblies. In remanufacturing, all of the motor’s components will be disassembled, cleaned, reconditioned and reassembled.

The project’s participants aim to build a process chain from inbound inspection to end-of-line testing. Each step of the process will have its own demonstrator and test rig – from initial inspection, disassembly, demagnetisation, cleaning, component diagnosis and remanufacturing, through to reassembly and end-of-line testing, where the motor’s functionality will be assessed.

“For instance, during this process, a motor housing with minor wear might be classified for re-use and, if necessary, reconditioned using machining processes to ensure functionality,” Große Erdmann explains. “Depending on the chosen value preservation strategy, different process steps and chains are involved, so the effort for reconditioning may vary.”

One of the challenges will be disassembling and re-using magnetic materials. “A rotor with permanent magnets is difficult to disassemble into its components even in a manual disassembly process due to the coating and bonding of the magnets,” the researcher points out. “Here, the goal is to establish non-destructive disassembly methods.”

An AI tool being developed as part of the project will help to choose the best value-retention strategy for an application. It will have access to the motor’s product and process data, saved as a digital twin.

The knowledge gathered in the project is intended to be used to design new electric motors. The goal is to develop a prototype motor that can be easily disassembled and to which value-preservation strategies can be applied.

“Innovative value-retention strategies offer significant potential for emission reduction in terms of sustainability,” says Große Erdmann.

As well as Schaeffler and Fraunhofer, the Reassert project members include the Karlsruhe Institute of Technology, Bright Testing, iFakt and Riebesam.

Schaeffler: Twitter LinkedIn Facebook

Fraunhofer IPA: X LinkedIn Facebook