- Home » News » Product News

Rectangular track system supports payloads up to 40kg

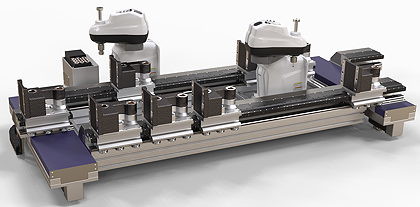

The UK linear motion specialist HepcoMotion has developed a new guidance system for Beckhoff Automation’s XTS smart conveyor technology that moves items along rectangular paths. By removing the XTS system’s curved segments, the new GFX-r system can handle payloads of up to 40kg

The absence of the curved motor sections allows the movers to be stronger, more powerful and to have larger mounting platforms, while maintaining their accuracy, durability and agility. Mover speeds of 4m/s and press loads up to 1.5kN are possible. The new system also offers a repeatability of 10µm, even when moving 30kg payloads at speeds of 3m/s.

With its high load-bearing capability, the new system is expected to have a significant impact in many sectors including automotive, aerospace, and logistics. It is also suitable for machine cells incorporating robots, power tools and sensors, as well as for automated assembly and inspection systems.

The new system builds on a decade of cooperation between Hepco and Beckhoff on smart linear conveyors in the form of the GFX/XTS combination. In that time, there has been a major uptake of SCT (smart conveyor technology), with benefits in terms of performance, service lives and flexibility. There are already thousands of metres of GFX/XTS in use in industries including pharmaceuticals, food processing, packaging, and battery assembly.

XTS uses linear motors to drive and control movers independently around a track, enabling work processes of varying durations to be combined, products to be changed on the fly, and workstations to be added or removed. Hepco's GFX guidance system provides the transport path, guiding the movers mechanically along the motor modules. It can absorb substantial forces acting on the movers, ensuring precise alignment and resistance to deflection.

The new system combines Beckhoff and Hepco’s TMS (Track Management System) with the increased drive capacity of XTS seven- and ten-pole magnet arrays. By removing the curved sections, larger movers with longer magnet arrays can be used, reducing heating losses by up to 60%. TMS completes the rectangular path, transitioning movers between tracks.

The GFX-r system is available in four- or six-bearing versions offering high strength and stability. It uses existing GFX/XTS parts including GFX-PRT2 straight slide hardware, base plates and motor brackets, as well as Beckhoff’s XTS motors and its TwinCat control system.

HepcoMotion: X LinkedIn Facebook

Beckhoff Automation: Twitter LinkedIn Facebook