- Home » News » Technology News

Motor sensor is low-cost rival to magnetic and optical encoders

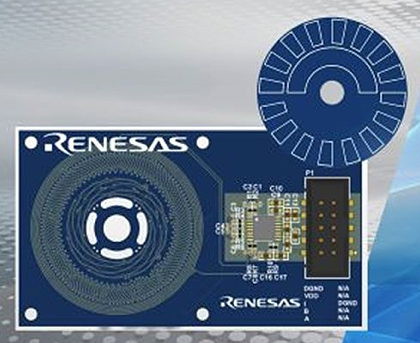

The Japanese semiconductor specialist Renesas has developed an inductive motor position sensing technology to rival the costly magnetic and optical encoders commonly used in motor control applications. The company claims that its high-speed inductive position sensor (IPS) technology is accurate, robust, reliable and cost-effective.

The proprietary IPS technology uses sensing elements consisting of copper coils etched onto a PCB (printed circuit board) that detect the position of metallic targets. Unlike magnet-based sensors, the dual-coil IPS sensors can operate at speeds of up to 600,000 rpm (electrical) and detect the motor position at start-up. The sensors have a propagation delay of less than 2μs, making them suitable for motors operating at high rotational speeds. The technology also offers auto-calibration and linearisation, ensuring consistent performance throughout a motor’s life.

The dual-coil technology, based on the Vernier principle, supports a resolution of up to 19 bits and an accuracy of up to 14 bits, making it superior to comparable technologies on the market, according to Renesas. The absolute sensors will operate reliably in harsh environments, where they can be exposed to high temperatures, dust, moisture, vibration and electromagnetic interference.

The sensors are also immune to stray fields, need no maintenance, and are less susceptible to error than magnetic sensors. Conventional optical or magnetic-based encoders tend to be heavier and more expensive.

“Our induction position sensor technology represents a significant leap forward in motor position sensors,” says Jan Leuckfeld, senior director in Renesas’ HPC Analog (Sensor) division. “They will enable us to provide differentiated motor position sensor ICs for industrial applications that are robust, highly accurate and cost-effective.”

“Position sensors for factory floors must endure extreme conditions such as humidity, high temperatures and vibration,” adds Ulrich Marl, key account manager at the German encoder manufacturer Lenord+Bauer, which is a Renesas customer. “Through our collaboration with Renesas, we’ve integrated IPS-based technology into our encoder portfolio to ensure reliability and safety, while reducing downtime in critical applications.”

The induction position sensor technology will support UART, ABI and I2C communications, for integration into industrial networks, and supporting real-time monitoring and data analysis. Over-voltage, reverse-polarity and short-circuit protection are built in.

The new sensor technology will be backed by a toolchain that includes dedicated software for user customisation and precision optimisation.

Renesas plans to combine the new sensor with compatible devices from its own portfolio to offer optimised, low-risk designs with fast times-to-market.

Mass production of the new sensors is planned for the second quarter of 2024.