- Home » News » Technology News

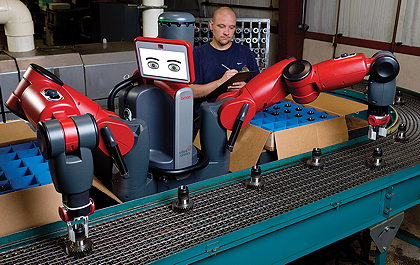

Two-armed robot adapts to changes on the factory floor

The US robot developer Rethink Robotics has announced a “groundbreaking” technology that will allow its Baxter collaborative robot to adapt to changing, real-world environments. The Robot Positioning System – part of the latest upgrade to Rethink’s Intera software – helps users to re-deploy robots after common plant-floor disturbances such as tables being bumped or fixtures being moved.

The technology enables the two-armed Baxter robots to switch between tasks without retraining by using environmental markers – called Landmarks – in conjunction with its embedded vision system. The robot recognises the locations of the markers and, if these change slightly, can mark the new locations and adjust its movements accordingly. By adapting to common changes on the plant floor, Rethink Robotics says it is making it easier for manufacturers to deploy Baxter across a variety of applications.

“Manufacturing robots have always been caged, not only to protect the workers around them from harm, but also to protect their precisely configured environments from being disrupted by those same workers,” explains Rethink Robotics’ CEO, Scott Eckert. “With Baxter, we brought the manufacturing robot out of its cage by making it safe enough to work next to people. Now, we’ve made it safe for the robot to work effectively in real-world conditions as well, by allowing it to adapt to everyday variations that people naturally produce.”

Users can define an operating environment with up to 20 Landmarks, saving time and resources when switching the applications that Baxter is working on. The new software allows the robot to adapt quickly to changes of up to ±50mm horizontally and within ±10 degrees of rotation. The result is an automation system that can adapt readily to common variations in its environment – saving time and helping to keep production lines running.

One of the first customers to use the new technology, Michigan-based Praxis Packaging Solutions, had to be able to reconfigure its production lines rapidly.

“We need our people and our automation to effectively work in a semi-structured, and sometimes variable, manufacturing environment,” explains Chris Hager, Praxis’ information technology manager. “Rethink’s Baxter robot, particularly with the new Robot Positioning System, provides a solution that can finally adjust to the changing conditions of our work cells. No other robot built for manufacturers can come close to providing the flexibility and adaptability of Baxter.”